Medallion Labs’ Color Testing Capabilities

Ensuring consistent color in your food products is crucial for maintaining quality and appealing to consumers. At Medallion Labs, we offer a range of color testing services to help you achieve this.

We provide three primary methods: Hunter, Lovibond, and Minolta, each with unique advantages. This blog post will explore the importance of color measurement in the food industry, detail our color testing options, and explain the testing process.

Why is Color Measurement Important For Food?

Color is a key factor influencing consumer perception of food quality, freshness, and taste. Inconsistent color can raise concerns about product integrity, even if the taste and nutritional value remain unchanged. Visible color differences are particularly impactful when products are displayed in packaging.

Color analysis plays a vital role in:

- Quality Control: Monitoring color consistency throughout the production process.

- Process Verification: Ensuring that processing steps (e.g., toasting, adding dyes) are correctly implemented. The Hunter method is particularly useful for this.

- Supply Chain Management: Identifying variations in ingredients from different suppliers, allowing for proactive adjustments.

- Objective Measurement: Overcoming the subjectivity of visual assessments, which can be affected by lighting, packaging, and individual perception. Color testing provides objective, repeatable, and comparable data.

How Do You Test For Color In Food?

Our color analysis protocols adhere to strict standards to ensure accuracy and reproducibility. Six key conditions are meticulously controlled:

- Illuminant: The type of light used for measurement (e.g., daylight, incandescent). Consistent illuminant is crucial for accurate comparisons.

- Color space: The three-dimensional system used to represent color data (e.g., Lab*).

- Observer: The standardized observer model used to calibrate color perception.

- Illumination geometry: The angle and direction of light during measurement.

- Sample prep: How the sample is prepared (e.g., ground, whole, diluted).

- Sample introduction: How the sample is presented to the instrument.

By carefully controlling these variables, we minimize sources of error and ensure reliable results.

Comparing Our Color Testing Methods:

- Hunter Color Test: Our most popular method, offering flexibility, precision, and robustness. Our research-grade Hunter colorimeter allows for diverse measurement approaches, including the detection of metameric differences (colors that appear the same under one light source but different under another). It provides various indices and is ideal for comprehensive color analysis.

- Lovibond Color Test: Specifically designed for refined and clarified oils, this method assesses the degree of aging or refinement.

- Minolta Color Test: A portable spectrophotometer, perfect for on-site color measurement in production facilities. Its portability and ease of use make it ideal for quick, real-time assessments.

Physical Testing

At Medallion Labs, our physical testing capabilities help ensure your food products are consistent in color, from ingredients to the process, and from one customer experience to the next. Contact us to learn more about our physical testing capabilities.

See TestsL*a*b* Color Scale and the Hunter Color Test:

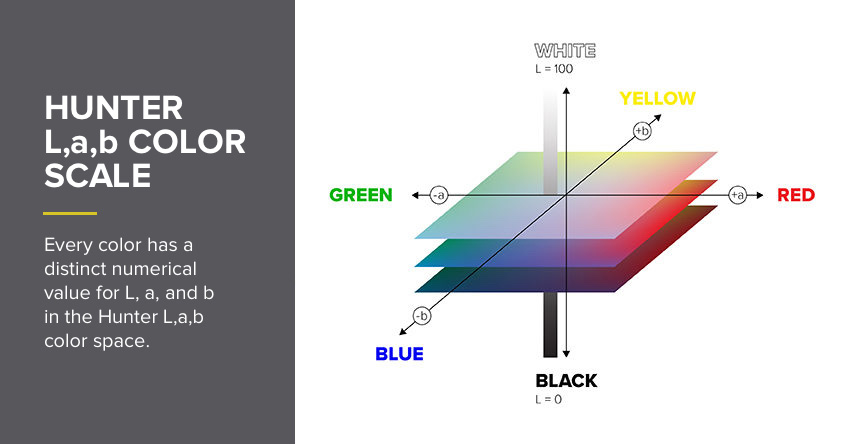

The Hunter color test utilizes the Lab* color scale, a three-dimensional system that mirrors human color perception:

L:* Represents lightness (0 = black, 100 = white).

a:* Represents the red-green axis (+a* = red, -a* = green).

b:* Represents the yellow-blue axis (+b* = yellow, -b* = blue).

This system allows for precise comparisons between samples and against pre-established standards. Our testing accommodates various sample types, including liquids, powders, solids, and particulates.

Lovibond Color Testing

- Specificity: The Lovibond system is highly specialized for analyzing the color of refined and clarified oils. It's not a general-purpose color measurement technique like the Hunter system. Its primary application lies in assessing the color characteristics of oils, providing insights into their quality and processing.

- Methodology: Lovibond uses a visual comparison method, often involving glass color standards. A sample of the oil is placed alongside a series of colored glass standards, and the color of the oil is visually matched to the closest standard. The Lovibond color is then reported using a specific notation system (e.g., Lovibond Red, Lovibond Yellow). This system is based on a scale of colored glass filters that have been standardized over time.

- Applications: Key applications include:

- Oil Refining: Monitoring the color of oils during the refining process to ensure consistent quality.

- Quality Control: Assessing the color of finished oils to meet specific standards and specifications.

- Aging Assessment: The color of oil can change over time due to oxidation and other factors. Lovibond measurements can help assess the age and potential degradation of an oil.

- Grade Determination: In some cases, the Lovibond color is used to determine the grade or quality of an oil.

Minolta Color Testing

- Instrumentation: Minolta (now part of Konica Minolta) produces a range of portable spectrophotometers. These instruments measure color objectively by analyzing the spectral reflectance or transmittance of a sample. They provide numerical data, eliminating the subjectivity of visual comparison methods.

- Portability: A key advantage of Minolta spectrophotometers is their portability. This allows for on-site color measurements in various locations, including production lines, warehouses, and even in the field. This real-time data collection is valuable for quality control and process monitoring.

- Applications: Minolta spectrophotometers are versatile and used in a wide range of applications, including:

- Quality Control: Monitoring color consistency throughout the production process.

- Color Matching: Ensuring that the color of a product meets pre-defined specifications.

- Formulation Development: Assisting in the development of new products with specific color characteristics.

- Supply Chain Management: Verifying color consistency of materials from different suppliers.

Your Reliable Partner for Food Product Color Analysis:

Medallion Labs provides accurate, reliable, and actionable color data to food producers, supporting informed decision-making throughout the production process. We offer a cost-effective approach to maximizing your testing budget.

Contact us today at 1-800-245-5615 or order online to learn more about our color testing services and other quality assurance solutions.

Let's Get to Work!

Submit your order online and ship your samples today. If you have questions, we are always here to help.

Medallion Labs+

A food testing program designed with mid-market and enterprise food and ingredient manufacturers in mind.